-

PRE-TREATMENT

Pre-treatment of water of any origin (city water to ground water) for either industrial use or for next steps of treatment. Based on water analysis, Elettracqua can design and build a system to control or remove turbidity and particulates, hardness and metals, organics and impurities, oxitating agents. According to your needs that system can contain:

- Dualmedia filtration

- Cartridge filtration

- Water Softening units

- Chemical injection systems

- Particle removing filters

- Ultrafiltration

- Microfiltration

- In-line ultraviolet units

- Antiscalant injection systems

- Heat exchangers

-

Double Pass Reverse Osmosis

Reverse Osmosis (RO) is a technology based on a semi-permeable membrane that is premeable to water but impremeable to other substances as salts, endotoxins and bacteria. Reverse osmosis membrane salt removal is over 99.5%, the double pass RO configuration is able to guarantee with high reliability the compliance with the Pharmacopeias requirements for Purified Water (PW). ELETTRACQUA plants are tailor made to meet every specification of the end customer requirements.

-

Reverse Osmosis + EDI

Reverse Osmosis with Elettrodeionizaiton is a water treatment system for producing non-compendial and compendial Purified Water (PW) meeting the USP and European Pharmacopeia, JP Pharmacopeia requirements.

-

Water For Injection (WFI): Multiple effects distillation unit

ELETTRACQUA multiple effects distillation unit consists of different evaporation sections each provided of liquid disengaging section and a final condensing unit. The system operates in the most efficient manner since only the first column is using plant steam. The rest of the system heats up from the first column generated steam and at the end, while the steam has to cool down to become liquid, an additional DTS heat exchanger is used to preheat the water inlet. The heart of any distillation system for WFI production is the steam separator. It is installed on top of the evaporation column to separate water droplets from the produced pure steam. The separator is based on the cyclone effect that produces centrifugal forces to draw all non gas droplets out of the main stream.

-

Pure Steam Generators – PS

Pure steam is used in all sterilization procedures that will secure all surfaces that are in contact with the raw product. For this reason its quality is critical in the pharmaceutical production. The steam generators of the DLSG series have been designed to meet the quality requirements of the pharmaceutical and biotechnology industry. These generators are used for the steam supply in autoclaves, SIP processes for the sanitization of lines, tanks and / or reactors and in all those applications where high quality steam is required. There are different configurations according to two main characteristics:

- Type of steam generated - Clean steam, Pure steam, apyrogen ultrapure steam

- Heating system used - electric, industrial steam, combination of the previous

-

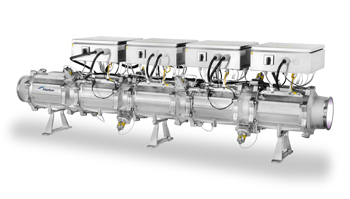

UV Disinfection

Our company exclusively represents ATLANTIUM TECHNOLOGIES (Israel) in Greece. ATLANTIUM has unique expertise in water disinfection using UV radiation and has developed innovative ways in which UV light can be used to microbiologically secure water. Having developed the Hydro-Optic™ technology, ATLANTIUM holds more than 60 patents, while the systems it manufactures are certified, by independent bodies, according to the strictest international standards EPA, FDA, NVI and PMO, with recognized certification for 4-log virus inactivation and 5-log microbial inactivation.

UV HOD systems utilize Total Internal Reflection (TIR)* technology, which recycles UV light energy, ensures uniform distribution of radiation dose throughout the irradiation chamber and offers greater poer efficiency (kW), compared to conventional UV systemsFor more please click here